An inclination sensor is a device that is used to measure the angle of inclination or tilt of an object with respect to the ground or a reference plane. These sensors are commonly used in a variety of applications, such as in mobile phones, tablets, and other portable electronic devices to detect the orientation of the device, in automotive and aerospace systems to measure the attitude of a vehicle, and in construction and mining equipment to monitor the stability of a structure or machine.

The working principle of an inclination sensor is based on the concept of gravitation and the properties of matter. The sensor consists of a weighted mass that is suspended within a housing by means of a flexible support, such as a spring or a flexure element. When the sensor is tilted, the weight of the mass causes it to shift or move within the housing, resulting in a change in the position of the mass relative to the housing.

This change in position is detected by various types of sensors, such as capacitive, inductive, or piezoelectric sensors, which are used to measure the displacement of the mass. The output of these sensors is then processed by a microcontroller or other electronic circuit, which calculates the angle of inclination based on the measured displacement and the known properties of the mass and the housing.

In some cases, the output of the sensors may be directly related to the angle of inclination, such as in the case of capacitive sensors, which use the change in capacitance between two electrodes to measure the displacement of the mass. In other cases, the output of the sensors may be a more complex signal, such as in the case of inductive sensors, which use the change in inductance between a coil and a magnet to measure the displacement of the mass.

Regardless of the specific type of sensors used, the output of the inclination sensor is typically in the form of an electrical signal, such as a voltage or a current, which can be easily processed and interpreted by electronic circuits and systems. This electrical output can then be used to control other devices or systems, such as motors, actuators, or displays, or to provide feedback to the user or operator of the device.

One of the key advantages of inclination sensors is their ability to operate over a wide range of angles, from a few degrees to as much as 360 degrees. This allows them to be used in a variety of applications, such as in aircraft and spacecraft to measure the orientation of the vehicle, in construction and mining equipment to monitor the stability of the structure or machine, and in robotics and automation systems to control the movement and positioning of the robot or machine.

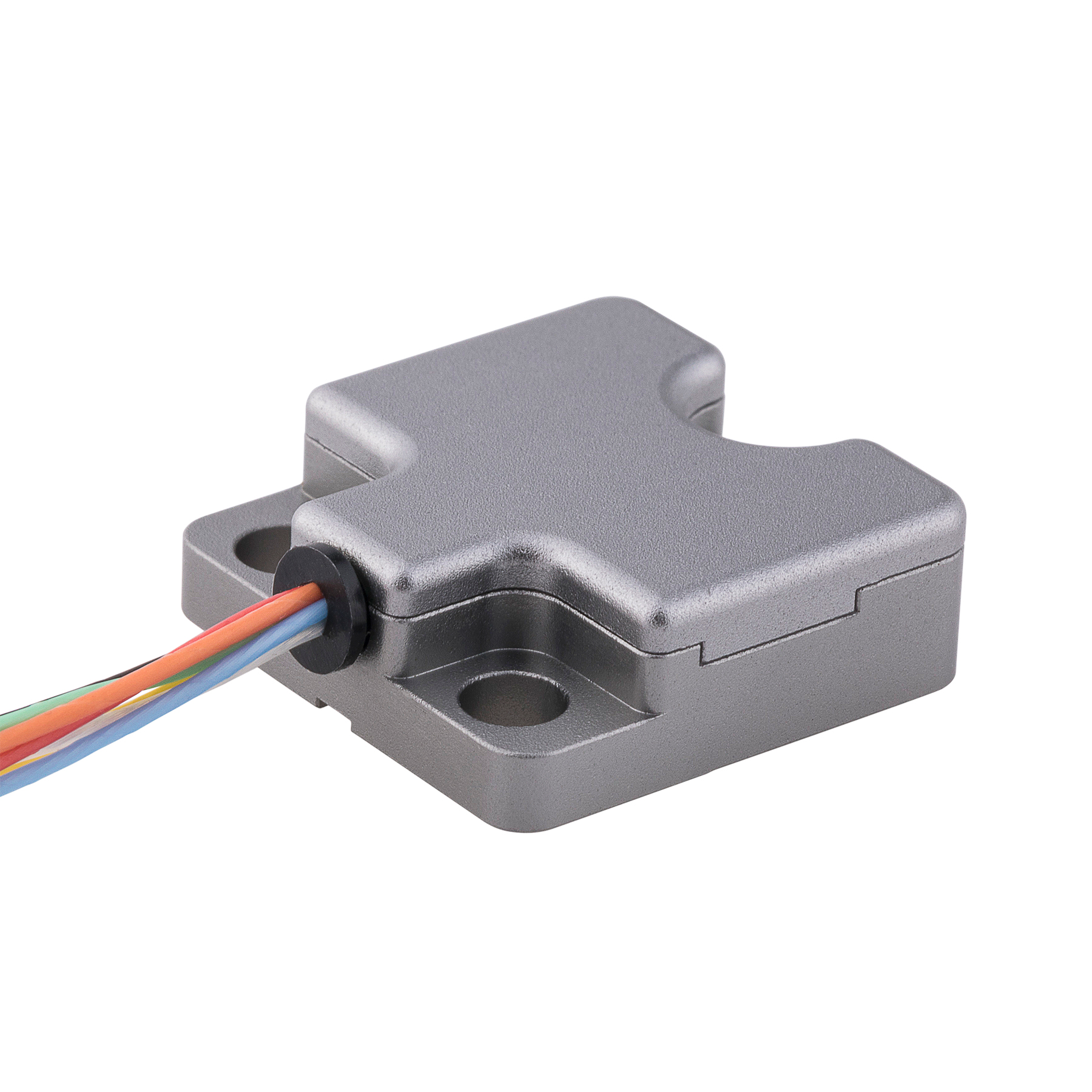

Another advantage of inclination sensors is their robustness and durability. These sensors are typically designed to withstand harsh environments and extreme conditions, such as high temperatures, moisture, vibration, and shock. This makes them ideal for use in applications where reliability and durability are critical, such as in automotive and aerospace systems, where the sensors must operate reliably even under extreme conditions.

In conclusion, inclination sensors are essential components in a wide range of applications, from mobile phones and tablets to aircraft and spacecraft. These sensors are based on the principles of gravitation and the properties of matter, and they use a variety of sensors and electronic circuits to measure the angle of inclination or tilt of an object. Their wide range of operation and robustness make them ideal for use in a variety of applications where precise measurement of inclination is required.