In fields like aerospace, industrial UAVs, and autonomous systems, knowing the precise orientation of a vehicle is essential for stability and control. Whether it’s a drone hovering in place or a high-speed target aircraft maneuvering through tight turns, accurate pitch and roll data are critical.

While GNSS and magnetometers help with general positioning and heading, they often fall short in fast-moving or vibration-heavy environments. That’s where a Vertical Gyroscope System becomes indispensable.

Designed specifically to measure pitch and roll angles, this system maintains high accuracy even under strong vibration, shock, and rapid motion. It’s a go-to solution for platforms like helicopters, oil-powered drones, and high-speed unmanned vehicles—anywhere that real-time, stable attitude data is needed to ensure safe and precise operation.

What is a Vertical Gyroscope System?

At its core, a Vertical Gyroscope System is an attitude measurement unit specifically designed to determine the vertical orientation of a moving object—primarily its pitch and roll—with respect to the Earth’s gravity vector. It uses a combination of gyroscopes, accelerometers, and digital signal processing (DSP) to determine real-time orientation, even when subjected to high-frequency vibrations and shock forces.

Unlike conventional IMUs that measure raw angular velocities and linear acceleration, vertical gyroscope systems offer direct output of attitude angles, and are optimized for stability in harsh environments, such as those involving gas turbines, propellers, or rapid maneuvers.

Core Components and How It Works

A typical vertical gyroscope system integrates several key elements:

| Component | Function |

|---|---|

| 3-Axis MEMS Gyroscope | Measures angular velocity around three orthogonal axes |

| 3-Axis Accelerometer | Senses linear acceleration to aid attitude estimation |

| High-Speed DSP Processor | Processes raw data using advanced fusion algorithms |

| Attitude Fusion Algorithm (Kalman Filter) | Calculates pitch and roll angles in real-time |

| Optional Interfaces (GNSS, Magnetometer) | Enables upgrade to GNSS/INS hybrid navigation system |

Using these inputs, the system outputs accurate pitch and roll attitude angles in both static and dynamic conditions. The presence of disconnect logic (used in aviation-grade gyros) helps suppress pitch/tilt corrections during high longitudinal accelerations or hovering, preventing attitude drift.

Technical Specifications: Performance Under Pressure

Modern vertical gyroscope systems are engineered to thrive under extreme mechanical stress. The following specifications highlight the performance of a high-end MEMS-based vertical gyroscope:

| Parameter | Specification |

|---|---|

| Static Attitude Accuracy | < 0.2° |

| Dynamic Attitude Accuracy (Hovering) | < 1.0° |

| Gyro Range | ±300°/s or ±800°/s |

| Accelerometer Range | ±5g or ±10g |

| Input Voltage | 9–36VDC |

| Operating Temperature | -40°C to +70°C |

| Shock Resistance | 20g/11ms |

| Vibration Tolerance | 6g RMS @ 10–2000Hz |

| Size | 71.5 x 71.5 x 53.5 mm |

| Weight | Compact & Lightweight |

These characteristics make it clear that vertical gyroscope systems are tailor-made for applications where shock, vibration, and environmental extremes are the norm.

Why Choose a Vertical Gyroscope Over a Standard IMU?

While IMUs (Inertial Measurement Units) are widely used for navigation, they may not offer the precision, ruggedness, or attitude stability required in extreme motion environments. Here’s how vertical gyros compare:

| Feature | IMU | Vertical Gyroscope System |

|---|---|---|

| Attitude Output (Roll/Pitch) | Requires fusion | Direct & calibrated |

| Dynamic Attitude Accuracy | Moderate | High |

| Resistance to Vibration/EMI | Medium | Excellent |

| Survivability in Harsh Environments | Limited | Military-grade |

| Suitability for UAVs/Helicopters | Moderate | Optimal |

| Shock Handling | 5–10g | Up to 20g |

Vertical gyroscope systems are not just about measuring rotation—they are engineered for attitude control in aircraft, marine systems, and any platform exposed to dynamic forces.

Key Advantages of a High-Shock Vertical Gyroscope System

1. Robust Shock and Vibration Resistance

One of the standout features of modern vertical gyroscopes is their ability to remain stable even under:

-

6g vibration across 10–2000Hz

-

20g shock loads within 11ms impulse duration

This resilience makes the system ideal for oil-powered UAVs, rotary aircraft, or fast-moving drones, which experience frequent mechanical stress during flight and landing.

2. Wide Sensing Range for Custom Applications

Gyro and accelerometer ranges can be customized to ±300°/s or ±800°/s for angular motion and ±5g or ±10g for acceleration. This flexibility supports a wide array of mission profiles, from slow hover flight to high-speed attack drones.

3. Military-Level Build Quality

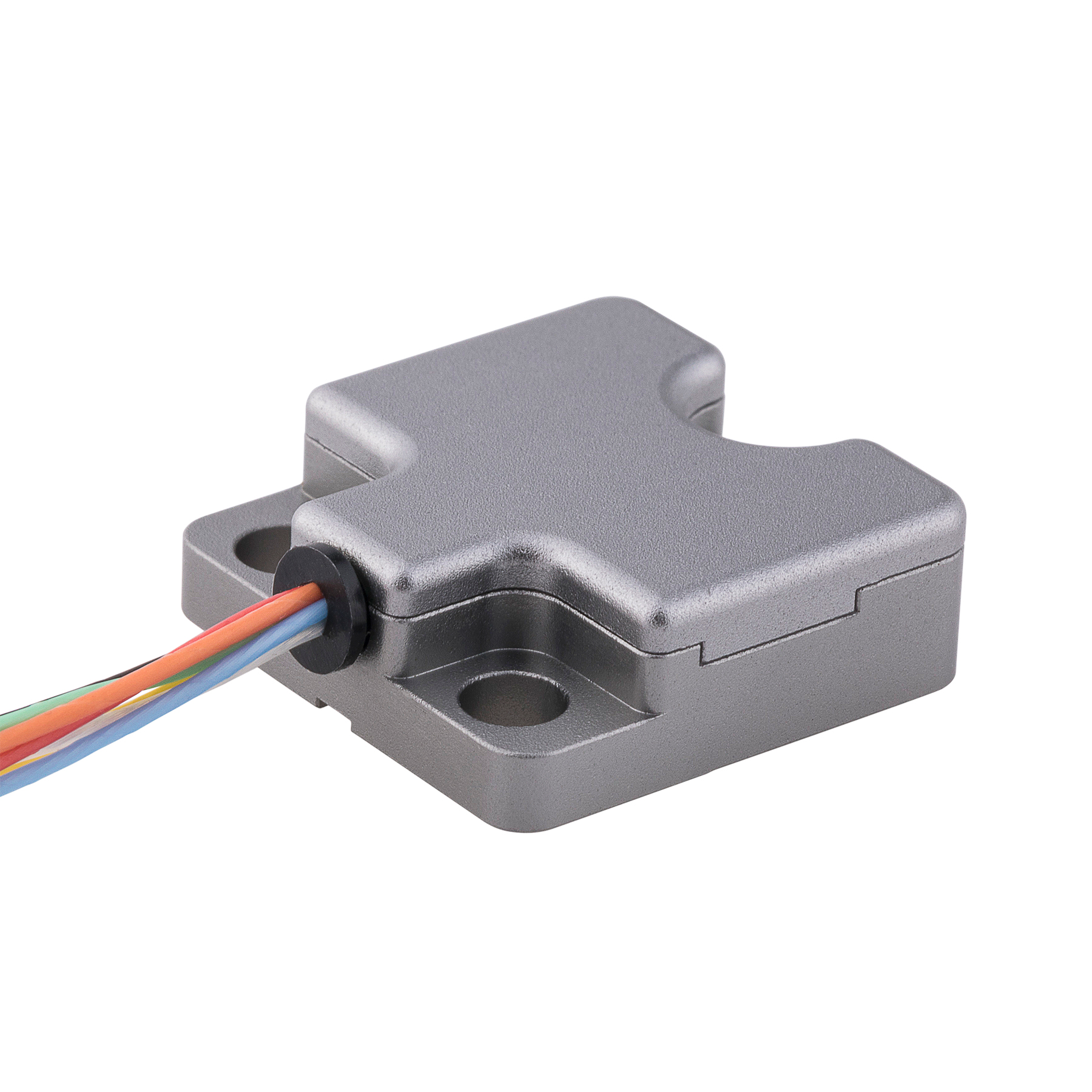

High-end vertical gyroscope systems are enclosed in military-grade aluminum alloy housing, designed for survivability in extreme temperatures (-40°C to +70°C), moisture, dust, and electromagnetic interference.

4. Expandable and Intelligent

Many vertical gyros support external sensor integration, such as:

-

Differential GNSS receivers

-

3-axis magnetic compasses

-

Barometers

This allows the unit to evolve into a complete GNSS/INS navigation system with yaw angle output and multi-source sensor fusion, enabled through Kalman filtering and advanced DSP.

5. Lightweight and Compact

Measuring just over 7cm per side, the vertical gyroscope system is extremely compact and can be integrated into UAV payload bays, gimbals, or even miniaturized guided platforms. Its low mass ensures minimal impact on flight dynamics.

Applications Across Industries

Unmanned Aerial Vehicles (UAVs)

Drones—especially industrial and oil-powered UAVs—require reliable attitude data for:

-

Hover stabilization

-

Path correction

-

Target tracking

-

Return-to-home behavior

Vertical gyroscopes ensure smooth flight even under engine-induced vibration and wind disturbances.

Helicopters and Rotorcraft

Rotorcraft generate significant vibrations due to rotor dynamics. Vertical gyroscopes offer stable pitch and roll feedback that can be used for:

-

Attitude correction

-

Stability augmentation systems (SAS)

-

Terrain-following and obstacle avoidance

High-Speed Target Drones

Defense training platforms such as target drones demand sensors that survive high-G launches and shock events. A vertical gyroscope provides precise post-launch attitude data needed for accurate flight path control and telemetry.

Autonomous Marine Craft

In high-speed watercraft and marine drones, maintaining upright stability and reducing pitch/roll drift is essential. The vertical gyroscope helps stabilize these platforms, particularly in wave-rich environments.

Precision Industrial Robotics

Certain ground robots or mining vehicles need robust orientation data for navigation in enclosed or GNSS-denied spaces. The shock-absorbing properties of vertical gyroscopes make them fit for rough terrains, factory automation, and heavy-duty transport systems.

Integration and Calibration: A Production-Grade System

High-end vertical gyroscope systems are factory-calibrated using 12-step calibration processes, which may include:

-

Temperature compensation

-

Bias and scale factor calibration

-

Cross-axis alignment

-

Noise filtering and stability checks

The sensor is also encapsulated using specialized adhesives and shielding to ensure long-term reliability, even under constant field use.

Customization and ODM Support

Manufacturers often offer ODM (Original Design Manufacturing) options for customers who require:

-

Specific voltage input ranges

-

Custom firmware or output formats

-

Modified sensor range for unique dynamics

-

Special mounting configurations

This customization flexibility makes the vertical gyroscope system an attractive solution for OEMs, system integrators, and research institutions.

The Vertical Gyroscope System—Precision Built for Motion

In the world of motion sensing, where vibration, shock, and rapid dynamics are daily challenges, the Vertical Gyroscope System rises as a dependable and precise solution. Its accuracy, shock resistance, compactness, and expandability make it a preferred choice in sectors ranging from UAV development to military training systems.

Whether embedded in a drone stabilizer or powering attitude sensors for marine guidance, vertical gyroscopes deliver unwavering performance where other sensors falter.

As automation expands, and the boundaries of unmanned systems push further, the vertical gyroscope system remains a critical enabler—ensuring machines always know which way is up.