1. Introduction: What is Dual Axis Tilt Sensors Used for?

Dual-axis tilt sensors are used for measuring the inclination of a device to the horizontal plane. In this post, we will explain what dual-axis tilt sensors are and some applications it is used in.

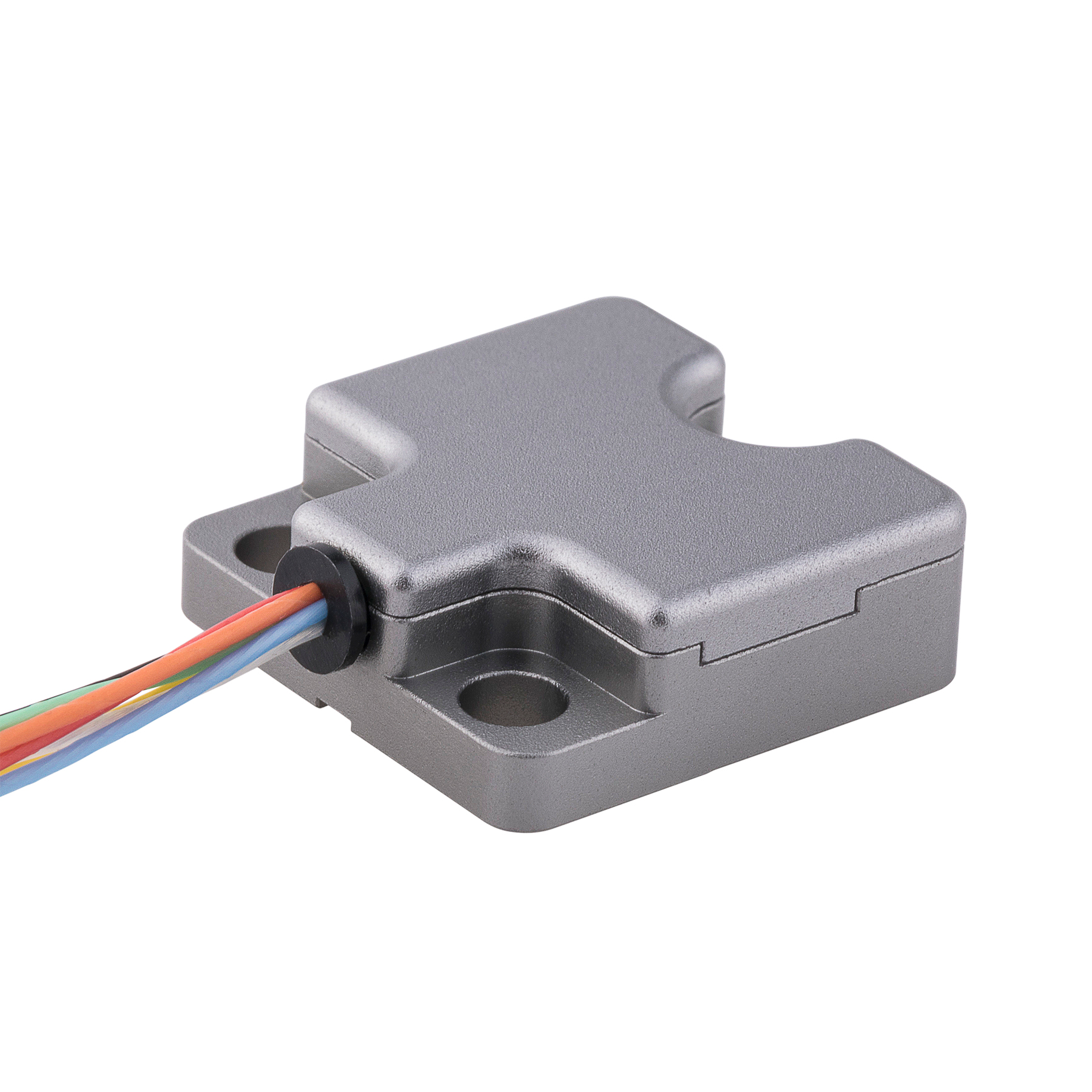

For those unfamiliar with dual-axis tilt sensors, they basically consist of two identical MEMS-based chips, which can be mounted on two identical base units. The base unit can be installed on any kind of device such as a crane, forklift, fork truck, etc., which has its own kind of platform to install the sensor on so that it is always in the same position. In that way, it can measure the inclination of the device based on gravity alone (hence its name). This is a very cost-effective solution because there is no need for an external power supply and weight when using a large number of devices with high accuracy.

There are several applications where dual axis tilt sensor is used:

- Measuring inclination angle for a solar tracker system

- Crane Monitoring System: This application uses a dual axis tilt sensor to measure vertical position as well as inclination angle. Note that both measurement angles could be obtained at once by two different configurations (i.e., horizontal controller and vertical controller in one basic configuration, or a combination thereof).

- Weighing Station: Many people prefer weighing their items at the outweighing station because they do not need any moving parts when they weigh their items (such as often happens in supermarkets). Dual axis tilting makes this possible by eliminating gravity from the equation (which makes it very robust due to its inertial nature).

2. Dual Axis Tilt Sensors in the Solar Tracker System:

Have you ever bought a solar tracker and wondered how it works? It’s pretty simple actually: the Solar Tracker System is an inclinometer. A dual axis tilt sensor measures the angular position of the device relative to a reference frame perpendicular to its axis of rotation. It also measures four other angles (anti-reflection, plus-minus, plus-minus again, and zero degrees)It’s because of this that the Solar Tracker System can be used to track objects up to 100 meters away. Typically, solar tracker installation involves mounting the tracker on a pole or post with a focus tracking mechanism that guarantees that the tracker stays on top of whatever it is tracking. The focus tracking mechanism is usually an articulated arm with two ball bearings at each end that can rotate freely in relation to its base. Once mounted on a pole or post, a single ball bearing at each end allows it to move up/down when tilted.

3. Dual Axis Tilt Sensors in Crane Monitoring:

Dual Axis tilt sensor is a cost-effective high-performance MEMS-based inclinometer, which has been widely used in the Solar Tracker System, Crane Monitoring, etc.

So what does it measure?

At nearly 0.5°, the dual axis tilt sensor measures ground motion variations. It does this at a very high rate of speed — up to 40 Hz for the dual axis tilt sensors on the R/C and about 10 Hz for the gyro on the sway bars. It can be used to compensate for uneven terrain, as well as to measure wind speed and direction.

Its low resolution allows it to be mounted on horizontal planes, while its high resolution allows it to be mounted on vertical planes using an adapter screw system. The dual axis tilt sensor comes with a unique removable cable that connects to both ends of the cable connecting it with a sensor such as an inclinometer or gyroscope.

4. The Advantages of Dual Axis Tilt Sensors:

The main use for dual axis tilt sensors is in solar tracking systems. The basic principle of solar tracking is to measure the angle of the Sun (for example, see Solar Tracking Systems). There are several ways to measure the angle of the Sun, but the most common one is by using a compass to detect the magnetic field. The magnetic field is then converted into a vector which can be used to determine whether or not the sun is directly in front of you. A compass has three independent axes: X, Y, and Z; when a compass is pointed at you directly (or at any object that you can see) it will point along lines parallel to its axes.

However, even with these two axes, there are many angles that cannot be measured directly: for example, if you stand in front of an object and point your compass towards it (which will be perpendicular to its axis), then your compass points along lines at an angle that depends on where you are standing. This makes it very difficult to use a compass as a way of determining whether or not you are facing an object or something else (such as objects behind you).

Dual Axis Tilt Sensors solve this problem by measuring both X and Y independently (and Z only if the object being detected has no other axes). In addition, they have been used for inspecting rocks and other minerals before drilling holes in them for geothermal energy exploration in order to prevent damage from drilling shock waves.

The principle behind dual axis tilt sensors is actually quite simple: they detect two different directions simultaneously with respect to their sensor axis. By detecting only one direction at any given time, they can provide more accurate measurements than can other sensors due to their ability to detect small changes in direction over time.

5. The Disadvantages of Dual Axis Tilt Sensors:

Inclinometers are used in many industries, from industrial to agricultural and even in the military field. They are especially useful for the product market, where the product’s stability is important.

While having a dual-axis sensor might initially seem like an attractive thing for being able to measure both angles and follow angles, there are some practical disadvantages of using such sensors:

- The sensitivity of most dual-axis tilt sensors is not that high so it is hard to integrate them into products that require high accuracy. In addition, the positioning accuracy of most dual-axis sensors is less than ±0.1°. However, they can be used as a reference angle sensor that can be used at different angles on different surfaces and when combined with other tilt sensors (such as radiometric or other hardware components) can provide an accurate correction for any non-vertical position difference.

- Dual axis sensors have more problems with drift and therefore need more accurate calibration techniques.

- The output of dual-axis tilt sensors must be converted into polar coordinates which need to be digitized by software before being stored in the device’s onboard memory (typically 1 or 2 bits). This makes it hard to control how much data should be sent out (and hence how much processing power should be consumed) when sending data to external devices such as web interfaces or mobile apps.