Inclinometer sensors are devices used to measure the inclination or tilt of an object in relation to gravity. These sensors are used in a wide range of applications, including industrial, automotive, and surveying. In this article, we will compare two types of inclinometer sensors: mechanical and electronic.

Introduction

Inclinometer sensors are widely used in various industries, such as construction, transportation, and robotics. These sensors are used to measure the inclination of an object in relation to gravity. The two main types of inclinometer sensors are mechanical and electronic. Mechanical inclinometer sensors use a liquid or bubble level to measure inclination, while electronic inclinometer sensors use accelerometers or gyroscopes. In this article, we will compare the two types of inclinometer sensors and discuss their advantages and disadvantages.

Mechanical Inclinometer Sensors

Mechanical inclinometer sensors use a liquid or bubble level to measure inclination. These sensors are relatively simple and inexpensive, and they can be easily integrated into existing systems. However, mechanical inclinometer sensors have some limitations. For example, they may not be able to measure small angles or high-frequency vibrations. Additionally, the liquid or bubble level may be affected by temperature changes or air bubbles, which can lead to inaccurate readings.

Electronic Inclinometer Sensors

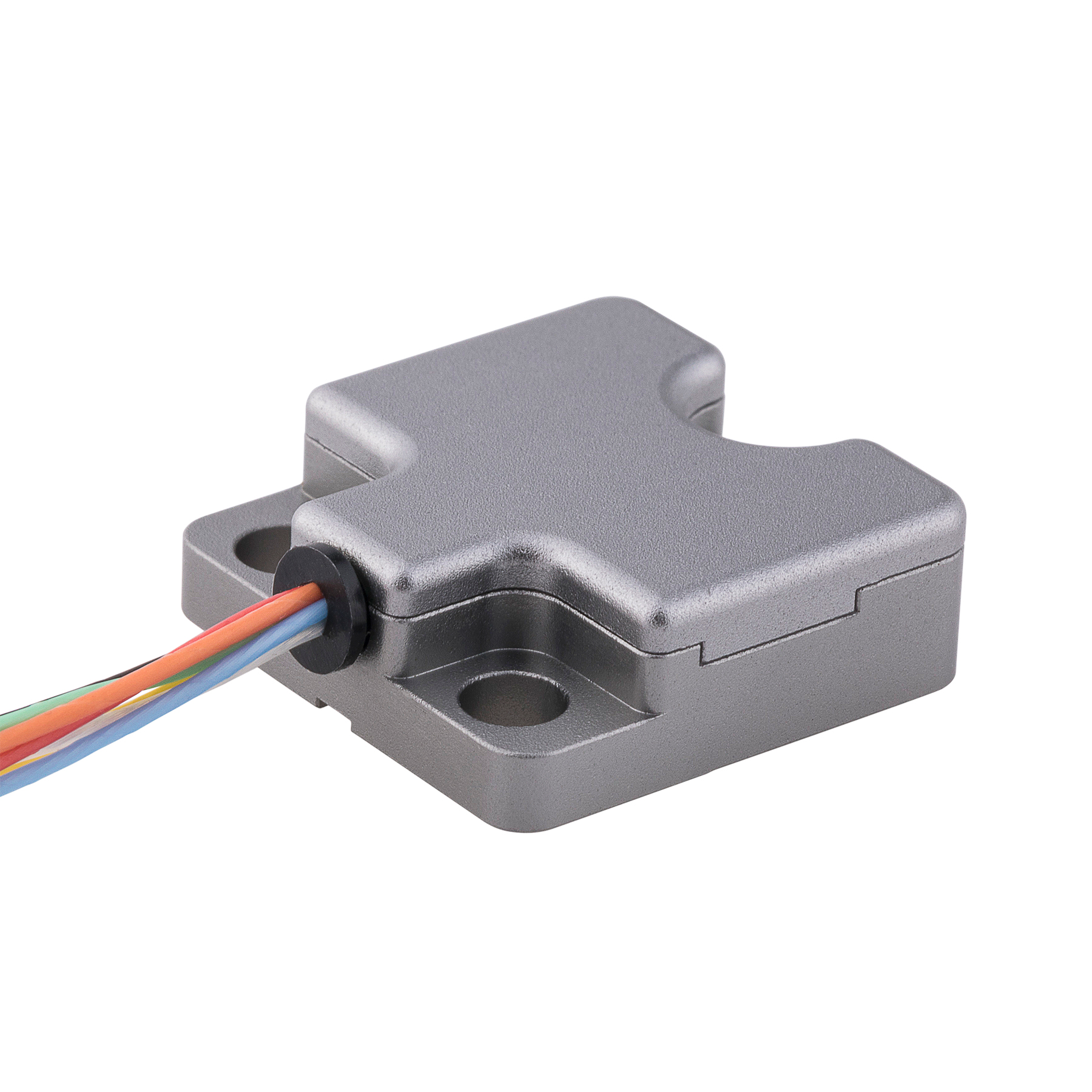

Electronic inclinometer sensors use accelerometers or gyroscopes to measure inclination. These sensors are more accurate and precise than mechanical inclinometer sensors, and they can measure small angles and high-frequency vibrations. Electronic inclinometer sensors are also more resistant to temperature changes and air bubbles. However, electronic inclinometer sensors are typically more expensive than mechanical inclinometer sensors and may require additional calibration.

Advantages and Disadvantages

In summary, mechanical inclinometer sensors are relatively simple and inexpensive, but they may not be able to measure small angles or high-frequency vibrations. Electronic inclinometer sensors are more accurate and precise, but they are typically more expensive and may require additional calibration.

Conclusion

In conclusion, both mechanical and electronic inclinometer sensors have their advantages and disadvantages. The choice between the two types of sensors will depend on the specific application and requirements. Electronic inclinometer sensors are more accurate and precise, and they can measure small angles and high-frequency vibrations. However, they are typically more expensive and may require additional calibration. Mechanical inclinometer sensors are relatively simple and inexpensive, but they may not be able to measure small angles or high-frequency vibrations. When choosing an inclinometer sensor, it is important to consider the specific requirements of the application and to compare the advantages and disadvantages of the different types of sensors.